|

Imperial Productions

®

Column

Base Replacements

Tuscan

& Attic

|

From

this......

|

To

this

|

|

Watch our

YouTube movie

about

Base Materials |

|

|

Rotted

Base Solutions |

|

|

If your base

is totally rotted inside and out like

this one, it is unlikely you will be able to save any

parts of it.

The base holds

the load of the shaft as it bears down

on the base.

If the

base is still partly good you can cut away

just the

rotted parts with a reciprocating saw and

retain the

good base core that will hold the load. As an option this load plug can be

covered with a hollow base made from ArchPolymerTM or FRP-PolyCompTM

|

|

|

Removing

the Base 3 Options

|

|

This

information is provide without prejudice and is intended as a

guideline only

- consult with your local structural engineer for advise and use licensed

trades for installation. |

|

1) Take down

the entire column and cut away

the old base and replace it with a new base or

we can make you part of the shaft in addition

to the new base to take the load of the shaft.

2) Attach

2x8's to the shaft sides to support the

column weight then cut away the old base totally

and replace part of the shaft and/or the base only

|

|

|

3) If the

center of the base is still good, cut away

all the profile sections of the rotted base leaving

just a load bearing

plug that takes the weight of

the shaft. Now cover this "plug" with a wood

or non wood hollow base.

If you want to purchase a non wood hollow

base you will need to retain your plug or buy

a new load bearing plug.

|

|

| 4)

Load on a base is effected by the fixed weight of the column shaft and the

additional weight of static loads such as snow and ice. Pressure on

the base is also effected by the stability of the substrate. If a concrete

under the plinth is broken, unstable or leaning, it will put undue

pressure on the column base, breaking it as the uneven pressure bears down

on the base. All plinths holding the base should have the

correct footings at a depth required by your local building codes and be

plumb.

If the base is

attached to a wood deck and not a plinth likewise the deck must be plumb

so that the weight of the shaft is disbursed evenly.

|

|

Watch our

YouTube movie

about

Base Materials => |

|

|

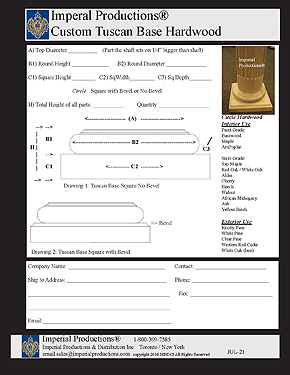

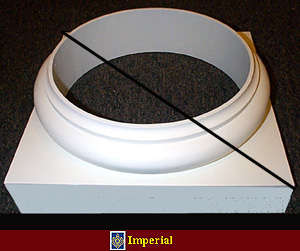

TUSCAN

HARDWOOD |

Custom Size

Form |

|

You cannot use

interior woods such as Poplar outside

Exterior Woods

include:

Knotty Pine:

Shellac the knots before painting

Clear Pine:

Some knots but small

Western Red

Cedar: Soft but Rot resilient

White Oak:

Extremely Hard

As solid wood,

they carry the load

of the column shaft All are custom

priced

|

|

|

|

|

HARDWOOD PARTS ARE

SOLD SEPARATELY |

|

You can order

just a Round Torus or just the Square Plinth

|

|

|

|

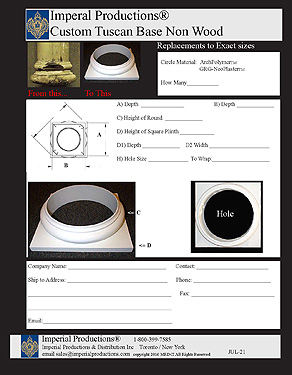

TUSCAN ArchPolymerTM

|

Custom Size Form |

|

ArchPolymerTM

is a synthetic composite

material.

It is rot, water, and insect resistant.

You can cut it

like wood, screw into it.

Some models

come primed. The bases are

hollow and

hold no load. They simply wrap

around a

shaft and load plug.

|

|

|

Click

for Material Properties |

| |

|

TUSCAN FRP-PolyCompTM

and FiberCompTM |

|

These two

materials are strong composites know as

FRP Fiberglass

Re-enforced Polymers. They are made

from Calcium

Carbonate, Marble Chips and Fiberglass

They are rot,

water, and insect resistant.

They are more

difficult to split but can be done

with a

reciprocating saw. They do not come primed.

The bases are

hollow and hold no load.

They simply

wrap around a shaft and load plug.

|

|

|

Click

for Material Properties |

Flexible Moulding Wrap

to Replace Broken Torus |

|

|

|

For

those that have a broken Torus here are two

SuperWiggly ResinMold®

casings

Remove the rotten round portion, provide us with

the circumference of the

existing Torus and apply

your SupperWiggly ResinMold®

|

|

|

ATTIC BASE HARDWOOD -

CUSTOMIZATION |

|

Hardwood

provides the ultimate

Customization

for Size as they are all

made to order.

Order your new

base as a standard

measurement or

we can create the

base with

specific measurements.

For example if

you want the plinth

to be 4"

high instead of 1-3/4"

It is possible

!

or the round

flat to be 8-7/8" instead

of 8 inches - It is

Possible !

|

|

|

Attic PDF Form Base and / or

Part Column Shaft |

|

|

|

ATTIC FRP-PolyCompTM

and FiberCompTM |

|

These two

materials are strong composites know as

FRP Fiberglass

Re-enforced Polymers. They are made

from Calcium

Carbonate, Marble Chips and Fiberglass

They are rot,

water, and insect resistant.

They are more

difficult to split but can be done

with a

reciprocating saw. They do not come primed.

The bases are

hollow and hold no load.

They simply

wrap around a shaft and load plug.

|

|

|

Click

for Material Properties |

|

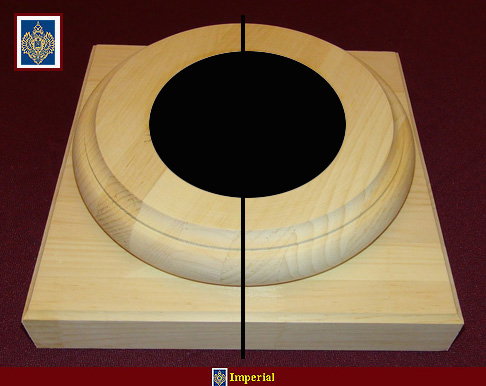

HARDWOOD SPLIT

& HOLE CUTTING

SERVICE |

|

|

All of our

bases can be ordered split for

shaft

wrap or easier installation.

The base is

created whole.

A center hole

is cut out so that the load

bearing shaft

can sit in the hole and on the

substrate. Then the base

is cut in 2 pieces to

wrap your

shaft.

With a

reciprocating saw, cut off the most of

the existing

rotted base. You will be left with

a load

bearing plug. If the center of your base

is still

good, then the shaft will reside on this

remaining plug.

The new wood

base will go around your

existing

plug. Glue the two pieces together.

|

|

Link

for Article |

|

|

|

|

|

NON-WOOD HOLE

CUTTING SERVICES |

|

Similar to the hardwood bases, a non wood

ArchPolymerTM

or PolyCompTM

base can be

ordered split

for reassembly around the

load bearing

plug. Specify straight cut or

cut on the

diagonal.

|

|

NON-WOOD

CUSTOMIZATION |

|

If you find the base you think will work, but it is not the right size, we

can customize

a hollow

ArchPolymerTM

base. Say for example you required the plinth to be higher than

the standard

model, a request for

quote can be made to create a modified custom base.

Changing the

hole size is more expensive than modifying the plinth size

|

|

|

|

<= Larger

Plinth

|

|

How to Order a

Custom Base: |

|

Send us an email with your name, address and phone number

We need to know the following:

1) Select

from a) Solid Hardwood

b) Hollow ArchPolymerTM

c) Hollow FRP-PolyCompTM

2) What is

the shaft Diameter at the bottom of the shaft that the new base will sit

on or wrap

Simply take a string and wrap it around the shaft - provide the length of

the string

This is the circumference of the bottom of the shaft

3) Will the

standard models work for you or do you need customization

4) If Custom

is needed Fill out

the following PDF form below and send it to us

with the measurements filled in on the form

5) How many

bases do you need

6) Send us

photos of your situation - the more we know the better we can help you !

|

|

Tuscan PDF Form

Base and

/ or Part Column Shaft

|

Attic PDF Form

Base and / or

Part Column Shaft

|

|

|

|

|

REAL METAL COATING

|

|

|

All of our

medallions can be metal coated in real metal

Select

from bronzes, silvers, golds, coppers for

a

special look.

Suited

well for the discerning client

or

commercial endeavor

|

|

ARTISAN PAINTING

AND STAINING SERVICE |

|

All of our

medallions can be ordered Painted or in

the case of

Hardwood - stained

Select from

our many historical colors of paints or

specify your

brand and number

|

|

Design Process

CAD or Concept

Drawings to New Creation is Required

Imperial Productions is a

Design House offering custom designs and historic reproductions of architectural

creations for the exclusive home or commercial offices and hospitality

buildings.

|

|

You Supply a

CAD Drawing |

|

We will

provide a custom quote as per your CAD drawing & details

Include

Elevations / Plan Views / Section Highlights

A full quote

will be provided. If you have Photos, Renderings or broken

parts they are

helpful for design clarity

|

|

Photo or

Rendering Supplied Only |

|

From a photo

we can provide an approximate budget price

This price

does not constitute a firm quote

For a firm

quote we require a CAD drawing and details

If you do not

have CAD drawing Imperial can be commissioned for

design

services that include Elevations / Plan Views / Section Highlights

The

cost of the CAD drawings will be quoted and can be applied to the

production of the

commission

|

|

Acceptance

of the Quote |

|

Submit

Payment |

For Custom Orders

Full payment is required

1) Money Orders

2) Company

Checks

3) Money Wire

Transfers

We do not accept Cash

or Credit Card on Custom Orders

|

|

Review

our Terms

|

click for=>

Imperial Sales

Policy

All custom orders

cannot be cancelled for any reason

|

|

Timing |

Once

Accepted, Timing starts from the time you sign

the shop

drawings not the Quote Date

|

|

Responsibility: |

Once you accept the

quote and sign off on the shop drawings,

the custom

product(s) will be

made to the closest measurements that

manufacturing

allows (providing for manufacturing tolerances)

Shop drawings

are made as a courtesy for detail confirmations. They must

be signed

back within 10 days or production begins without them.

Any major

changes noted on the shop drawings will be considered as

extras and

will be quoted accordingly as a schedule B which must be paid

prior to

production.

The application of

the product to the job site is the responsibility of the

architect,

designer, structural engineer, or contractor.

No affixing hardware

is supplied.

Any custom products

are made all sales final and cannot be

exchanged

or returned

|

Back to Custom Product

Main Page

|

How to Order Products 1-800-399-7585

416-264-6096

email:

sales@imperialproductions.com |

|

|

|

* All Prices & specifications in this website subject to change without

notice |

|

* Prices are net, Freight, Taxes & Duties charged where applicable otherwise

client is responsible for remittance |

|

* Measurements are approximate only, Final Product may vary from this

website |

|

COPYRIGHT MRDCI Martin Richards Design and Contracting Inc, Martin Richards DesignTM

and Imperial

Productions®

Feb 2018 all rights

reserved

|

|

Last

Update OCT-25 |

|