|

Building Components:

Columns / Domes / Balusters

|

FRP:

Fiberglass Product Specifications Mar-18

Rex Series

|

|

General

Description:

Rex Series FRP product consisting of gelcoat, polyester resin, and glass fibers.

It is weather

resistant and can be used in hurricane and earthquake zones and can be

submerged in water

All products are

made from molds and design can be created by Imperial Production or

supplied drawing

from specifier

|

|

Architect

Specification - Rex Series |

|

Part One -

General

A. Description - Internal and exterior architectural detail and millwork shall

be Rex Series FRP

-

as distributed by Imperial Productions and Distribution Inc.

Part Two - Submittals

A. Product Data: Submit manufacturer's descriptive literature, specifications,

installation instructions

and limited warranties.

B. Warranty: Manufacturer's Limited One Year Warranty is to be

submitted.

C. Product Material

Specifications: Obtain from the manufacturer for submission to the relevant

building code authority.

Part

Three - Substitutions

A. Substitutions from Imperial's specified architectural details and building

components will be

allowed only with the express written

consent of the Owner or Architect.

Part Four - Product Materials

A. All interior/exterior FRP products as distributed by Imperial

Productions & Distribution Inc.

B. Imperial distributed products are vermin resistant and

resistant to mold and mildew.

Part Five - Delivery, Storage and Installation

A. Deliver, store and install according to instructions as provided

by Imperial Productions & Distribution Inc.

B. Installation

instructions as provided by Imperial Productions & Distribution Inc. are to be

followed completely.

Use only recommended Adhesive

available from Imperial for installation in addition to mechanical fasteners.

|

|

Material

Specification - Rex Series |

|

Material Specifications

Flame Retardant Polyester Resins

Class 1 Flame

Spread per ASTM-E84 without addition of synergistic such as antimony trioxide

Resin can be

classified as high strength. Low Viscosity, exhibits wet-out

properties and low

drainage when

applied to surfaces. It is formulated with 35% styrene.

Applied in hand

lay-up, spray up, filament wound, and infused application processes.

|

|

a)

Mechanical Properties for Casting |

|

Property |

Value(SI) |

Value

(US) |

Method |

|

Tensile

Strength: |

77MPa |

11,200 psi |

ASTM-D638 |

|

Tensile

Modulus |

3.5GPa |

5.1 x 10(5)

psi |

ASTM-D638 |

|

Tensile

Elongation |

2.7% |

2.7%

|

ASTM-D638 |

|

Flexural

Strength |

120MPa |

17,800 psi

|

ASTM-D790 |

|

Flexural

Modulus |

3.5 GPa |

5.1x10(5) psi |

ASTM-D790 |

|

Heat

Distortion Temp |

68c |

156F |

ASTM-D648 |

|

b)

Mechanical Properties for 36% Glass Laminate |

|

Property |

Value(SI) |

Value (US) |

Method |

|

Tensile

Strength |

112 MPa |

16,200 psi

|

ASTM-D638 |

|

Tensile

Modulus |

7.4 GPa |

1.1 x 10 (6)

psi |

ASTM-D638 |

|

Flexural

Strength |

179 MPa |

25,900 psi

|

ASTM-D790 |

|

Flexural

Modulus |

6.5 GPa |

9.5 x 10 (5)

psi |

ASTM-D790 |

|

|

|

|

|

|

Optional: UV

resistance to Radiation

Standard mix

can be improved by adding up to 1% CYASORB UV-9 ultraviolet screener

|

|

Flame Test - Rex

Series |

|

E-84

Tunnel Test - Panel Thickness .086 inches - Class 1 FSI

ASTM-E84

E-84 Tunnel Test -

Panel Thickness .0666 inches - Class 1 FSI

E-162 Radiant Heat

Source Flammability Value 20 ASTM-E162

E-662 Optical Smoke

Density Flaming Exposure .22 @ 1.5 minutes ASTM-E662

41 @ 4 minutes

E-662 Optical Smoke

Density Non-Flaming Exposure .14 @ 1.5 minutes

8.2 @ 4 minutes ASTM-E662

Toxic Gas

Generation Flaming Exposure SMP 800c

CO (ppm) Max / Avg 443 / 363

CO2 (ppm) Max/Avg 4105 / 3272

SO2 (ppm) Max/Avg 4 / 3

Toxic Gas

Generation Non-Flaming Exposure SMP 800c

CO (ppm) Max / Avg 30 / 20

CO2 (ppm) Max/Avg 194 / 182

SO2 (ppm) Max/Avg 6 / 5

|

|

Regent

Series

FRP:

Fiberglass Product Specifications JUL-20

|

|

General

Description:

Regent Series FRP product consisting of gelcoat, polyester resin, and glass fibers.

The resin is a byproduct of

oil, natural gas, sand and other materials.

It is weather resistant and

can be used in hurricane and earthquake zones and can be submerged in water

All products are

made from molds and design can be created by Imperial Production or

supplied drawing

from specifier -

see our

levels of service click here

|

Architects Specifications

Part One - General

A. Description - Internal and exterior architectural detail and millwork shall

be Regent Series FRP

-

as distributed by Imperial Productions and Distribution Inc.

Part Two - Submittals

A. Product Data: Submit manufacturer's descriptive literature, specifications,

installation instructions

and limited warranties.

B. Warranty: Manufacturer's Limited One Year Warranty is to be

submitted.

C. Product Material

Specifications: Obtain from the manufacturer for submission to the relevant

building code authority.

Part

Three - Substitutions

A. Substitutions from Imperial's specified architectural details and building

components will be

allowed only with the express written

consent of the Owner or Architect.

Part Four - Product Materials

A. All interior/exterior FRP products as distributed by Imperial

Productions & Distribution Inc.

B. Imperial distributed products are vermin resistant and

resistant to mold and mildew.

Part Five - Delivery, Storage and Installation

A. Deliver, store and install according to instructions as provided

by Imperial Productions & Distribution Inc.

B. Installation

instructions as provided by Imperial Productions & Distribution Inc. are to be

followed completely.

Use only recommended Adhesive

available from Imperial for installation in addition to mechanical fasteners.

|

Material Specifications Physical Properties

a) Light weight: only 2 to 3 lbs per square foot

b) High strength and low weight

combination.

Stronger than steel - lite enough to make installation fast

c) Easy Part

consolidation - can be used to create traditional multi-tiered and multi-part

cornices, columns in one lift part

d) Low to zero maintenance -

long lasting

e) Weather resistant strong

enough to use in earthquake and hurricane zones

f) Highly resistant for high

impact areas such as shopping malls, public buildings

g) Fire Resistant: Meets

Class 1 Fire Rated ASTM-E84 requirements

- fire-retardant resins are used

h) Can be submerged in water

making it ideal for use in fountains and water displays

i) Can be coated easily for

desired color and texture

j) Glass Fiber -

Glass content 20 to 32%

k) Gelcoat 18mils

thick UV resistant

l) Laminate -

nominal thickness of 3/16" (.48cm)

Specify

additional thickness for required structural integrity

|

Manufacturing

Process:

It is manufactured in an

open mold. First the mold is sprayed with a gelcoat,

a durable

non-fading polyester coating.

The FRP

matrix (resin and fiber) is then applied to the mold with a chopper gun

or the hand lay up

process.

The FRP is then

compacted to remove excess air and allowed to cure.

|

Building Codes

As there are numerous

dominant Building Codes in existence and practice throughout

North America, in

addition to the many State-level

and Provincial

codes, Imperial strongly urges

Specifiers and users to refer to

their local codes as to the uses any building

components.

|

|

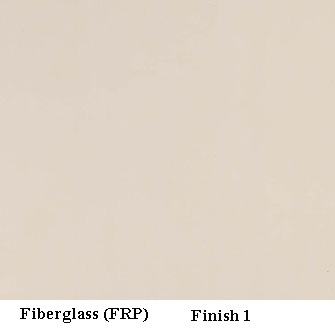

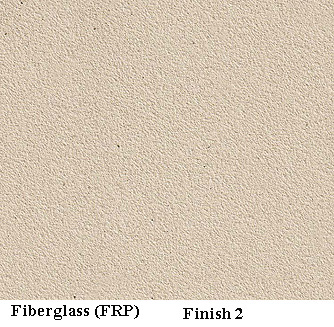

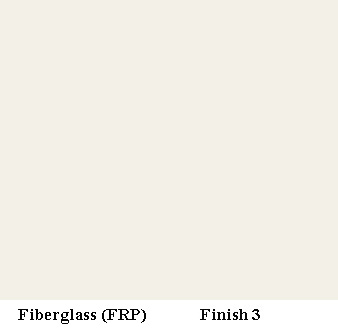

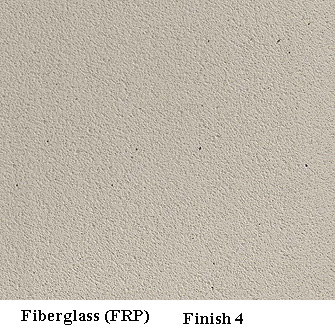

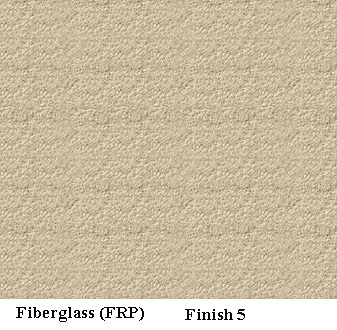

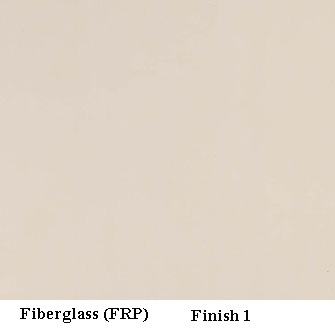

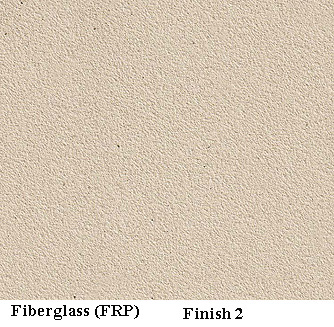

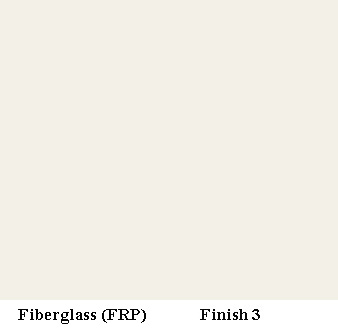

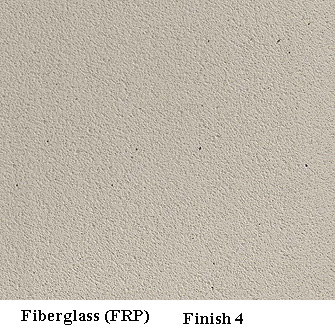

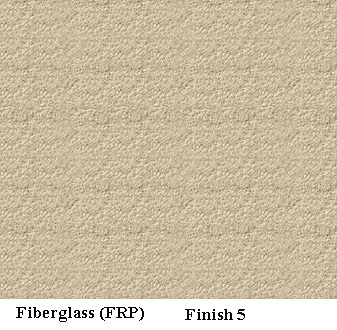

FRP: FIBERGLASSTM

Finishes

1) Unfinished

Sanded Gelcoat

2) Prefinished

(ie Finish 1 to 5

3) Factory

applied Urethane

4) Simulated

Stone

|

|

|

|

|

|

|

|

|

|

|

All Finishes are photo

representations only and may vary in reality and there

will be variances

in production |

Duchess

Series

Fiberglass

(FRP) Product Specifications

Updated Mar 2018 |

|

General Description:

Duchess Series

Fiberglass Columns are lite weight but extremely strong providing an economy for

installation but the

necessary strength for construction.

Manufactured with a

spray up fiberglass method.

|

|

Material

Properties:

Fiberglass and

Resin Materials

A) Glass cloth, matt

and "chop" shall be equal to the products of PPG-Owens Corning.

B) Polyester Resins

shall be Class A. The Resin will be flame retardant promoted thixotropic

polyester resin designed for use in hand lay-up and spray processes. The

resin is specifically

formulated for use in applications that require an ASTM-84 Class 1 flame spread

rating,

without the use of fillers or antimony trioxide, with an ASTM-84 flame spread

rating of 10

unfilled

C) Gel Coat shall be

part of system specified at a .015" to .025" thickness

D) Final ratio

materials shall be 25% fiber, 75% resin for the body of components

E) Shaft thickness

shall be 1/8" to 1/4" depending on size

F) Allowable

Tolerances

i)

Wind Load Resistance

FRP Components when installed shall resist all wind loading

as per the minimum wind loading requirements as the Standard Building Code

It is necessary to use hurricane brackets and related hardware as per the code

such

as Simpson Strong Ties

ii) Dimensional Tolerances of Finished units.

(1) Dimensions 10 Feet or under +- 1/4"

(2) Dimension 10 Feet to 20 Feet +- 3/8"

|

Material Physical

Properties:

Typical Range

A) Flexural Strength

psi @ 77 degrees F = 15,000 to 20,000

B) Flexural Modulus

psi @ 77 degrees F = 550,000 to 700,000

C) Tensile Strength

psi @ 77 degrees F = 10,000 to 18,000

D) Tensile Modulus

psi @ 77 degrees F = 700,000 to 850,000

E) Barcol Hardness =

45 to 55

F) Glass content 0/0

= 24% to 29.5%

G) Compression

Strength psi = 15,000 to 20,000

H) Water Absorption

= .04% to .05%

I) Thermal

Expansion (in inches/feet) = .000011 to .000012

Flammability

Properties (1/8" Glass Mat Laminate)

A) ASTM-E84

Tunnel Test = 10 (unfilled)

B) HLT-15

Rating = 100

C)

ASTM-D635-74 = AEB <1.0 CM, ATB < 5 sec.

D) ASTM

D-2863-74 Oxygen Index = 36.6

|

Building Codes

As there are numerous

dominant Building Codes in existence and practice throughout

North America and

the world, in

addition to the many State-level and Provincial

codes,

Imperial strongly urges Specifiers

and users to refer to their local codes as to the

uses any building

components before buying

product.

Fiberglass columns

are sold as building components not finished goods.

|

|

Manufacturers

Limited Warranty:

Fiberglass

columns are warranted to be free of structural defect to the original

purchaser for a

one year

period. Manufacturing will replace any column that has failed as a

result of defective

material or

workmanship. The manufacturer will not be liable for more than the

original purchase

price of the

said column. Manufacturing does not warrant against cost of

replacement or damages

resulting from

replacement of the defective column. It is the responsibility of the

customer to

ensure the

columns purchased are designed for their particular installation.

Any deviation from the

standard

installation voids all warranties.

|

Go Back to the Main Page

|

How to Order Products 1-800-399-7585

416-264-6096

email:

sales@imperialproductions.com |

|

|

|

* All Prices & specifications in this website subject to change without

notice |

|

* Prices are net, Freight, Taxes & Duties charged where applicable otherwise

client is responsible for remittance |

|

* Measurements are approximate only, Final Product may vary from this

website |

|

COPYRIGHT MRDCI Martin Richards Design and Contracting Inc, Martin Richards DesignTM

and Imperial

Productions®

Feb 2018 all rights

reserved

|

|

Last

Update APR-20

|

|